| |

|

| |

|

| HYDRAULIC SHEARING MACHINES |

||||||||||

|

||||||||||

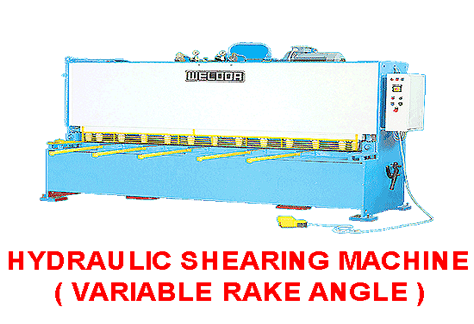

HYDRAULIC SHEARING MACHINE ( VARIABLE RAKE ANGLE ) "WELDOR" Hydraulic Guillotine shearing machine with variable rake angle have been designed and

developed through structural analysis technique for continuous production, accuracy and repeatability.

Note: Specifiation / Design are

subject to change without prior notice. |

||||||||||

![]()

Weldor Enginerring Private Ltd. Copy Right 2009 Rajkot - Gujarat - India