| |

|

| |

|

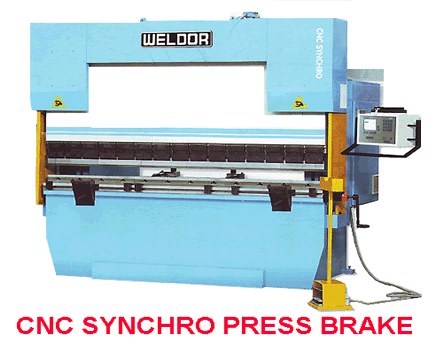

| CNC SYNCHRO PRESS BRAKE |

|||

|

|||

CNC SYNCHRO PRESS BRAKE OPTIONAL ACCESSORIES Note: Specifiation / Design are subject to change without prior notice |

|||

![]()

Weldor Enginerring Private Ltd. Copy Right 2009 Rajkot - Gujarat - India